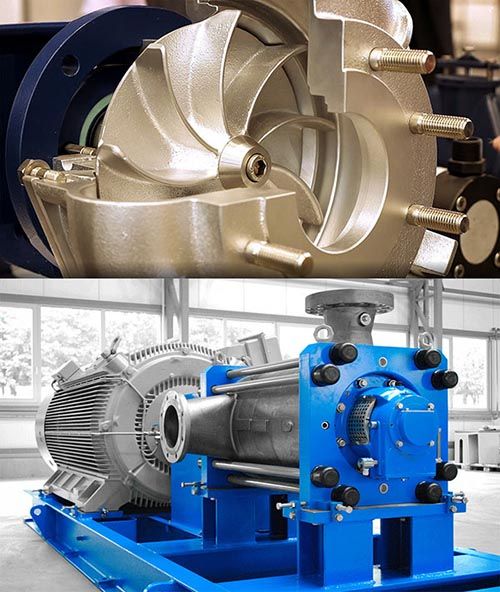

CENTRIFUGALNE PUMPE

Technical parameters: Capacity up to: 4.650 m3/h ; Head up to: 170 m (560 feet) ; Speed up to: do 1800 o/min ; Temperature: max. 215° ; Pressure up to: 30 bar ;For Higher pressures we offer special execution.

Sizes: DN 125 to DN 600 (5” to 24”)

Handled liquids: Clean or contaminated liquids (with or without bigger solids), Cold and hot water , Condensate and de-ionised liquids, Oil, brine and acid suspensions, Paper stock suspensions

Application: General industry, District heating, Chemical industry, Steel mills and mining , Sugar refineries , Pulp and paper mills